Aluminium (symbol: Al, atomic number: 13) is a chemical element with the atomic symbol Al and an atomic weight of 26.98u. It is a silvery-white, soft, non-magnetic and ductile metal in the boron group. It is the third most abundant element in the Earth's crust (after oxygen and silicon) and makes up about 8% by mass. It is also the most abundant metal in the Earth's crust, making up 8.2% of the total weight.

The History of Aluminium

Aluminium has a rich history dating back thousands of years when it was used to make jewelry and ornaments in ancient civilizations such as Ancient Egypt and Ancient Greece. However, it wasn't until the early 19th century that Aluminium was first isolated and identified as an element by Danish physicist and chemist, Hans Christian Ørsted. In 1827, German chemist Friedrich Wöhler produced a small sample of pure Aluminium by reducing Aluminium chloride with potassium amalgam. This sparked interest in the metal and led to further research and development.

In 1854, French chemist Henri Étienne Sainte-Claire Deville developed a method to produce larger quantities of Aluminium by electrolyzing molten cryolite. This process was expensive and time-consuming, making Aluminium a rare and valuable metal.

It wasn't until 1886 that American chemist Charles Martin Hall and French engineer Paul Héroult independently discovered the Hall-Héroult process, which is still used today to produce Aluminium on a large scale. This breakthrough led to the widespread use of Aluminium in various industries and made it more affordable for everyday use.

How Aluminium is Produced?

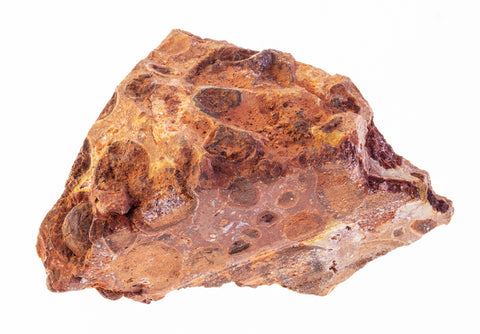

Step 1: Bauxite Mining

The first step in producing aluminium is to mine the raw material known as bauxite. Bauxite is a reddish-brown rock that contains high levels of aluminium oxide. It's typically found in tropical and subtropical regions, with Australia being the top producer of bauxite.

To extract bauxite, the topsoil and overburden are removed, revealing the bauxite ore. The ore is then extracted using heavy machinery and transported to a processing plant.

Step 2: Bauxite Refining

Once at the processing plant, the bauxite ore goes through a refining process. This involves crushing and grinding the ore into fine particles before mixing it with sodium hydroxide, also known as caustic soda. This mixture is then heated in a digester under high pressure and temperature to dissolve the aluminium compounds.

The resulting solution is then filtered to remove any impurities and solid particles, leaving behind a clear liquid containing dissolved alumina.

Step 3: Smelting

The next step is smelting, where the dissolved alumina is separated from the solution using an electrolytic cell. The cell is lined with carbon and acts as a cathode. When electricity passes through the cell, it causes a chemical reaction that produces pure aluminium.

The pure aluminium is then collected and cast into ingots or billets for further processing.

Step 4: Rolling and Extruding

The ingots or billets are heated and rolled into thin sheets or extruded into various shapes such as rods, bars, or tubes. This step is essential in creating different products from aluminium, such as cans, car parts, and construction materials.

Step 5: Surface Treatment

To enhance the appearance of aluminium products and protect them from corrosion, they undergo surface treatment. This can include anodizing, painting, or powder coating.

Step 6: Recycling

Aluminium is a highly recyclable material, and up to 95% of it can be recycled without any loss in quality. The recycling process involves melting down used aluminium products and reusing them to create new products.

Top Aluminium Producing Countries

According to the United States Geological Survey (USGS), China is the top producer of Aluminium, followed by Russia and Canada. Other top producers include India, United Arab Emirates, and Australia. These countries are rich in bauxite ore, the primary source of Aluminium production.

The Properties of Aluminium

Aluminium has many unique properties that make it a valuable metal for various industrial applications. It is a lightweight metal with a low density, making it ideal for use in transportation, packaging, and construction. It also has a high strength-to-weight ratio, making it strong enough to be used in structural applications.

One of the most notable properties of Aluminium is its resistance to corrosion. Unlike other metals that can rust or corrode when exposed to oxygen and moisture, Aluminium forms a thin layer of oxide on its surface, which protects it from further corrosion.

Aluminium is also a good conductor of heat and electricity, making it useful in electrical wiring and as a heat sink in electronic devices. It is non-magnetic and non-toxic, making it safe for use in food packaging and medical equipment.

Aluminium Prices

Aluminium is one of the most widely used metals in the world due to its unique properties such as low density, high strength, and resistance to corrosion. It has a wide range of applications in various industries, including construction, transportation, packaging, and electronics. As a result, the demand for aluminium is constantly increasing.

However, the price of aluminium is highly volatile, and it can be affected by various factors.

Supply and Demand

The basic economic principle of supply and demand plays a significant role in determining the price of aluminium. When there is high demand for aluminium but limited supply, its price tends to increase. On the other hand, when supply exceeds demand, the price of aluminium decreases. The production of aluminium is mainly concentrated in a few countries, including China, Russia, and Canada. Any disruptions in these countries' production can have a significant impact on global aluminium prices.

Cost of Production

The cost of producing aluminium is another crucial factor that affects its price. Aluminium production involves high energy costs, as it is an energy-intensive process. Therefore, fluctuations in energy prices can have a direct impact on the cost of production and ultimately affect aluminium prices.

Economic Growth

The overall state of the global economy has a considerable influence on the demand for aluminium. When economies are growing, there is higher demand for products that use aluminium, such as automobiles and construction materials. On the other hand, during times of economic downturn, the demand for aluminium decreases, leading to lower prices.

Political and Trade Policies

Political and trade policies can also impact aluminium prices. Changes in trade agreements or tariffs can affect the flow of aluminium between countries, ultimately affecting its price. Political instability or conflicts in major aluminium-producing countries can disrupt production and lead to fluctuations in prices.

Technological Advancements

Advancements in technology can also impact the price of aluminium. New production methods or technologies that reduce energy consumption and costs can lead to lower aluminium prices. Technological advancements can also lead to new uses for aluminium, increasing its demand and affecting its price.

Stock Levels

The level of aluminium inventories held by producers and traders can also affect its price. High inventory levels can indicate oversupply, leading to lower prices, while low inventory levels can signal a tight market and higher prices.

Currency Exchange Rates

Aluminium is a globally traded commodity, and its price is heavily influenced by currency exchange rates. Changes in exchange rates between major producing countries such as China and consuming countries like the United States or Europe can impact the cost of producing and trading aluminium, ultimately affecting its price.

Environmental Regulations

Environmental regulations can also play a role in determining aluminium prices. Stricter environmental policies and regulations on emissions or waste disposal can increase production costs for aluminium producers, leading to higher prices for consumers.

Consumer Behaviour

Consumer behaviour can have a significant impact on the demand for aluminium. As a versatile and lightweight metal, aluminium is used in various industries such as construction, transportation, and packaging. Consumer demand for products in these industries can affect the overall demand for aluminium and its price.

Economic Factors

Economic factors such as GDP growth, inflation rates, and interest rates can also impact aluminium prices. Economic downturns can lead to reduced demand for goods that use aluminium, resulting in lower prices. Conversely, economic growth can drive demand for products made with aluminium and increase its price.

The Benefits of Aluminium

The widespread use of Aluminium has numerous benefits for both individuals and industries. Its lightweight nature makes it ideal for transportation, reducing fuel consumption and emissions. It is also highly recyclable, with nearly 75% of all Aluminium ever produced still in use today.

In addition, Aluminium is a sustainable metal as it can be recycled indefinitely without losing its properties. This makes it an environmentally friendly choice for various industries.

Our Aluminium Range

- Aluminium Angle

- Aluminium Flat Bar

- Aluminium Round Bar

- Aluminium Square Bar

- Aluminium Channel

- Aluminium Rectangular Tube

- Aluminium Square Tube

- Aluminium Round Tube

- Aluminium Sheet Cut to Size

- Aluminium Sheet Full Sheets

- Aluminium Plate Cut to Size

- Aluminium T Section

- Aluminium Z Section

- Aluminium Five Bar / Chequer Plate Cut to Size

- Aluminium Five Bar / Chequer Plate full plates

- Aluminium Cope Mouldings

- Aluminium Easyfix

- Aluminium Double Feather Edge

- Aluminium J Sections

- Aluminium Hanging Z section

- Aluminium Half Round Moulding

- Aluminium Nosings

- Aluminium Wallboard Sections