Are you looking to embark on a DIY project or perhaps considering starting your own aluminium fabrication business? Look no further! In this comprehensive guide, we will take you through the world of cutting aluminium products. From traditional hacksaws to the modern marvels of waterjet cutting, we've got you covered. Whether you're a seasoned professional seeking new techniques or a beginner eager to learn the ropes, join us on this exciting journey and unlock the key to precision and efficiency in aluminium cutting. Get ready to transform raw metal into intricate masterpieces with the Aluminium Warehouse comprehensive guide to cutting Aluminium products!

Introduction to Cutting Aluminium Products

Aluminium is a lightweight and versatile metal that is used in various industries such as construction, transportation, and consumer goods. Its high strength-to-weight ratio makes it an ideal choice for many applications. However, cutting aluminium products can be a daunting task if you are not familiar with the proper techniques and tools.

There are various methods available for cutting aluminium products, each with its own advantages and limitations. The choice of method will depend on the type of project, material thickness, precision required, and budget. In the following sections, we will delve deeper into each of these methods to help you choose the right one for your specific needs.

Tools and Equipment for Cutting Aluminium

When it comes to cutting aluminium products, having the right tools and equipment is crucial for achieving precise and smooth cuts. Here are some of the most used tools and equipment for cutting aluminium:

- Hacksaw: A hacksaw is a hand tool that consists of a narrow blade attached to a handle. It is one of the most basic tools used for cutting aluminium, especially for smaller pieces or thin sheets. The blade can be easily replaced when worn out, making it a cost-effective option.

- Circular saw: This power tool has a circular blade that rotates at high speeds, making it suitable for cutting thicker pieces of aluminium with precision and speed. It can also be fitted with different blades depending on the type of cut needed.

- Jigsaw: Like a hacksaw, a jigsaw is also a handheld tool but uses a reciprocating blade instead of a continuous one. This allows for more intricate cuts in aluminium sheets or profiles.

- Compound mitre saw: Also known as chop saws, these power tools are versatile in their ability to make angled cuts on both wood and metal materials like aluminium. They have an adjustable arm that allows you to set the desired angle and make precise cuts.

- Bandsaw: A bandsaw consists of an endless looped blade that rotates around two wheels at high speeds, making it ideal for cutting thicker blocks or bars of aluminium quickly and accurately.

- Laser cutter: For more complex shapes or designs in aluminium products, laser cutters provide unparalleled accuracy with minimal material wastage. These machines use powerful laser beams to melt through the metal along pre-programmed paths.

- Waterjet cutter: Like laser cutters, waterjet cutters use highly pressurized streams of water mixed with abrasive particles like garnet or sand to erode through metals like aluminium without generating heat-affected zones or distortion.

- Plasma cutter: This tool utilizes an electrically conductive gas passing through a nozzle at high speeds to create an electrical arc that cuts through metals. It is a fast and efficient method for cutting thicker pieces of aluminium.

In addition to these tools, it is essential to have appropriate personal protective equipment (PPE) like safety glasses, gloves, and ear protection when using power tools for cutting aluminium to ensure safety and prevent any potential injuries.

Ultimately, the choice of tool or equipment will depend on the size, thickness, and complexity of the aluminium product being cut. It is always recommended to use the right tool for the job to achieve accurate and clean cuts without damaging the metal material.

Hacksaw

Hacksaws are a commonly used tool for cutting aluminium products, as they are affordable, portable, and easy to use. They consist of a frame with a thin, toothed blade stretched between its ends. The teeth on the blade can be set either facing towards or away from the handle, depending on the desired cutting direction.

Before using a hacksaw to cut aluminium products, it is important to choose the right type of blade. There are two main types of blades available – high-speed steel (HSS) and bi-metal. HSS blades are made from hardened carbon steel and are suitable for cutting softer materials such as aluminium. Bi-metal blades have a harder edge made from high-speed steel welded onto a tougher spring steel back, making them ideal for cutting thicker or harder materials.

Next, it is essential to securely clamp the aluminium product before beginning to cut with a hacksaw. This will prevent any movement or shifting while you cut and ensure cleaner and more accurate cuts.

When starting the cut, place the saw at an angle of about 45 degrees to the surface of the aluminium product. Use light pressure while guiding the saw along your predetermined line. It is crucial not to put too much pressure on the saw as it may bend or break under excessive force.

As you continue cutting through the metal, make sure that you regularly apply lubricant oil on both sides of the blade to reduce friction and keep it cool. This will also help prolong the life of your blade and improve its performance.

One common challenge when using hacksaws for cutting aluminium products is keeping track of your line while sawing through thick material. To overcome this issue, mark your cutting line with chalk or masking tape beforehand so that you have a visual guide while sawing.

Once you have completed your cut, be sure to remove any burrs or rough edges by gently filing them down with sandpaper or using deburring tools specifically designed for aluminium.

Hacksaws are a reliable and affordable tool for cutting aluminium products, but they do require proper technique and maintenance to achieve the best results. With the right blade, clamping technique, lubrication, and finishing steps, you can effectively use a hacksaw to cut through various types of aluminium products with ease. So, always keep these tips in mind before using a hacksaw for your next aluminium project.

Circular Saw

Circular saws are one of the most common and versatile power tools used for cutting aluminium products. They consist of a circular blade with sharp teeth that rotate at high speeds, allowing for quick and precise cuts. These saws can be handheld or mounted on a workbench, making them suitable for both small DIY projects and large-scale industrial applications.

When using a circular saw to cut aluminium, it is crucial to select the right blade. The type of blade will depend on the thickness and hardness of the aluminium being cut. For thin sheets and softer grades of aluminium, a standard carbide-tipped blade can suffice. But for thicker sheets or harder grades, it is recommended to use a specialized aluminium-cutting blade with more teeth per inch (TPI).

Before starting any cutting operation, it is essential to secure the aluminium piece firmly in place using clamps or vice grips. This will prevent it from moving around while cutting and ensure clean and accurate cuts. It is also advisable to wear protective gear such as safety glasses and gloves while operating a circular saw.

To achieve smooth cuts with minimal burrs or jagged edges, make sure that the blade’s tooth speed matches the rotational speed of the saw itself. If there is too much friction between the blade’s teeth and the metal surface, it can result in excessive heat generation leading to melted edges or warped pieces.

Circular saws come in various sizes with different motor powers. When working with thicker sheets of aluminium, opt for a larger diameter saw with higher horsepower as it can handle deeper cuts without stalling or overheating.

Another critical factor when using this tool is maintaining proper lubrication between the cutting edge and material being cut. Aluminium tends to stick to blades due to its high thermal conductivity; therefore, applying an appropriate lubricant such as beeswax or WD-40 can significantly improve efficiency by reducing friction.

It is vital always to keep an eye on your cut line while using a circular saw. The blades can produce sparks, which may cause burns or ignite flammable materials nearby. It is also recommended to use an adjustable guide or straight edge to ensure straight and accurate cuts.

Circular saws are excellent tools for cutting aluminium products as they provide speed, versatility, and precision. With the right blade, proper technique, and safety measures in place, you can achieve clean and professional cuts on your aluminium projects with ease.

Mitre Saw

A mitre saw, also known as a chop saw or drop saw, is a powerful cutting tool commonly used for making precise and angled cuts in various materials, including aluminium. It consists of a circular blade mounted on a hinged arm that can be adjusted to different angles for cutting accuracy.

When it comes to cutting aluminium products, using a mitre saw can significantly speed up the process and ensure clean, accurate cuts. However, there are certain considerations to keep in mind before using this tool.

Firstly, it is essential to choose the right type of blade for cutting aluminium. Most mitre saw blades are designed for woodcutting and may not be suitable for cutting metals. Look for carbide-tipped blades with fine teeth specifically made for aluminium cutting. These blades have smaller gaps between the teeth, which prevent the metal from catching and causing damage or kickback.

Next, ensure that your mitre saw is securely mounted on a stable work surface before use. This will prevent any accidents or injuries while operating the machine. Also, make sure that you understand how to use the safety features of the tool correctly.

Before starting your cut, double-check that your workpiece is firmly clamped in place and cannot move during cutting. Aluminium can be slippery and tends to vibrate when being cut; therefore, securing it properly is crucial to achieve precise cuts without any mishaps.

To get the best results with a mitre saw when working with aluminium products:

1) Make sure your blade is sharp – A dull blade will result in rough edges and increase the risk of kickback.

2) Adjust your blade speed accordingly – For thicker pieces of aluminium, lower speeds are recommended.

3) Use appropriate safety gear – Always wear protective eyewear and gloves when operating any power tools.

Additionally, it would help if you considered using a lubricant while making long cuts or working with thicker pieces of aluminium. This will reduce friction between the blade and metal, resulting in cleaner cuts and prolonging the life of your blade.

A mitre saw is a valuable tool for cutting aluminium products, but it requires proper handling and safety precautions. By choosing the right blade, securing your workpiece correctly, and using appropriate safety gear, you can achieve clean and precise cuts with ease. Remember to always follow the manufacturer's instructions and guidelines for safe usage of this powerful tool.

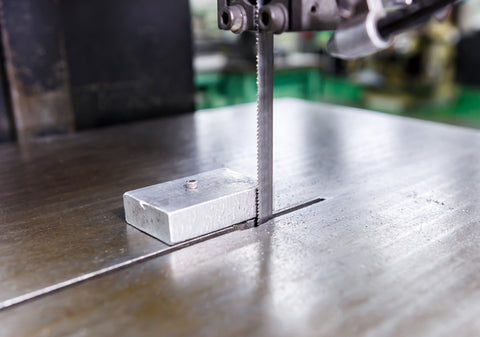

Horizontal Bandsaw

A horizontal bandsaw is a versatile and efficient tool for cutting aluminium. It uses a continuous band of toothed metal, known as a blade, to make precise cuts through various materials. This type of saw allows for horizontal movement of the material being cut, making it ideal for cutting large pieces of aluminium.

When it comes to cutting aluminium with a horizontal bandsaw, there are several things to keep in mind to ensure optimal results. Let's take a closer look at some important considerations when using this tool.

- Blade Selection: The type and quality of the blade used can greatly affect the outcome of your cuts. Blades designed specifically for cutting aluminium are recommended as they have teeth specially designed to handle the softness and tendency to clog of this material.

- Blade Tension: Proper tension on the blade is crucial for clean and accurate cuts. Too loose and the blade will flap around, resulting in rough edges; too tight and it may break or wear out faster than necessary.

- Clamping: Before starting any cut, be sure that your piece is securely clamped to prevent any movement while cutting. This will ensure straighter cuts and reduce the risk of accidents.

- Cutting Speed: The speed at which you feed your material into the saw depends on its thickness and hardness. For thin sheets or softer grades of aluminium, slower speeds are recommended, while thicker or harder pieces require higher speeds.

- Coolant/Lubricant: Using coolant or lubricant during cutting helps dissipate heat caused by friction between the blade and material, preventing warping or melting of the metal.

- Feed Pressure: It's important not to push too hard on the material being cut as this can cause vibrations that affect accuracy and increase wear on both machine and blade.

- Maintenance: Regular maintenance is essential for keeping your bandsaw in top condition. Keep an eye on saw guides, bearings, blades tension, and coolant levels to ensure smooth operation.

Mastering the art of cutting aluminium with a horizontal bandsaw requires attention to detail and proper technique. By following these guidelines, you can achieve precise cuts and make the most out of this versatile tool in your metalworking arsenal.

Vertical Bandsaw

A vertical bandsaw is a powerful and versatile tool that is commonly used for cutting aluminium. It consists of a long, continuous blade with teeth that move in a vertical direction, allowing for precise and efficient cuts. In this section, we will explore the features and benefits of using a vertical bandsaw for cutting aluminium, as well as some tips on how to master its use.

One of the main advantages of using a vertical bandsaw for cutting aluminium is its ability to make straight and precise cuts. The vertical movement of the blade allows for more control over the cut compared to other types of saws. This makes it ideal for cutting complex shapes or intricate designs on aluminium sheets.

Another benefit of using a vertical bandsaw is its versatility. With different blade sizes and tooth configurations available, it can be used to cut various thicknesses and types of aluminium, from thin sheets to solid blocks. This makes it an essential tool in any metalworking workshop.

When choosing the right blade for your project, consider the type and thickness of your aluminium as well as the desired cut quality. For thinner sheets or softer alloys, a fine-toothed blade would provide smoother edges while coarser blades are better suited for thicker or harder materials.

To achieve clean and accurate cuts with your vertical bandsaw, it's important to properly set up your workpiece before starting the machine. Make sure it is securely clamped onto the table with no loose edges that could get caught on the blade during operation.

As with any power tool, safety should always be a top priority when using a vertical bandsaw. Always wear appropriate protective gear such as safety glasses and gloves while operating the machine. Additionally, regularly check and maintain your saw according to manufacturer instructions to ensure safe usage.

To master the art of cutting aluminium with a vertical bandsaw takes practice and patience. Start by practicing on scrap pieces before moving on to more critical projects. Adjusting feed rates, blade tension, and tracking can also greatly affect the cut quality, so be sure to experiment with these settings for optimal results.

Jigsaw

Jigsaws are a versatile tool that can be used for various types of cuts, including straight lines and curves. They feature a small, fine-toothed blade that moves up and down in a reciprocating motion. This type of blade makes them ideal for cutting through softer materials like aluminium without causing damage or leaving rough edges.

One of the main advantages of using a jigsaw for cutting aluminium is its ability to make precise cuts. The fine-toothed blade allows for more control over the cut, resulting in smoother edges and cleaner lines. Jigsaws also come with adjustable speed settings, allowing you to adjust the speed according to the thickness and density of the material being cut.

Another benefit of using a jigsaw is its portability. These handheld power tools are lightweight and easy to manoeuvre, making them suitable for both small DIY projects and larger scale jobs. They also tend to produce less noise compared to other power tools, making them more suitable for indoor use.

Tin Snips

The first step in mastering the art of cutting aluminium with tin snips is selecting the right tool for the job. There are three main types of tin snips - straight-cutting, left-cutting, and right-cutting. Straight-cutting snips have blades that cut straight ahead, while left and right-cutting snips have blades that curve towards their respective directions.

For cutting aluminium sheets, straight-cutting tin snips are usually recommended as they provide a cleaner and more accurate cut. However, if you are working on a curved or angled edge, then left or right-cutting tin snips may be more suitable.

It's also important to consider the material thickness when choosing your tin snip. Most standard tin snips can handle up to 3mm aluminium sheets easily. However, if you're working with thicker sheets, opt for aviation or compound-action tin snips which offer more power and leverage.

Plate Saw

Plate saws are a popular tool for cutting aluminium products, predominantly aluminium plate, due to their versatility and precision. Also known as table saws or panel saws, these powerful machines are typically used in woodworking but can also be used for cutting metal materials like aluminium.

The basic design of a plate saw consists of a circular blade mounted on an arbor that is driven by an electric motor. The blade can be adjusted to different angles and heights, making it suitable for various types of cuts. The size of the blade can also vary depending on the type of plate saw, with larger blades able to make deeper cuts.

One major advantage of using a plate saw for cutting aluminium is its ability to make straight and precise cuts. The flat surface of the table provides stability to the material being cut, ensuring accurate results every time. This makes it ideal for projects that require high levels of precision, such as creating aluminium frames or panels.

In addition to straight cuts, plate saws can also be equipped with special blades that allow them to make angled or curved cuts in aluminium products. This adds versatility to the tool and expands its range of applications. Furthermore, some models come with adjustable fences and guides that help users create intricate designs and shapes in their aluminium pieces.

When purchasing a plate saw for cutting aluminium, it is essential to consider the type and thickness of aluminium you will be working with. Some models may have limitations in terms of the size and type of material they can cut, so be sure to choose one that meets your specific needs.

Guillotine

A guillotine is a specialised cutting tool that is commonly used for cutting aluminium sheet. It consists of a flat, sturdy blade that is mounted on a frame and operates like a large pair of scissors. The blade is typically made of high-quality steel and can be adjusted to different angles to achieve precision cuts.

One of the main advantages of using a guillotine for cutting aluminium is its ability to produce clean, smooth edges. This makes it ideal for projects where accuracy and aesthetics are essential, such as in the manufacturing of aluminium frames or panels. The sharpness of the blades and the steady pressure applied by the frame allow for effortless slicing through even thick sheets of aluminium with minimal effort.

In addition, guillotines are also known for their speed and efficiency. With one swift motion, it can cut through long strips or stacks of aluminium with ease, making it perfect for mass production or larger scale projects. Unlike other cutting tools like hacksaws or hand shears, which require continuous manual effort, guillotines offer a more streamlined process that saves time and energy.

When using a guillotine to cut aluminium products, there are some important safety measures to keep in mind. Firstly, always wear protective gear such as gloves and goggles to avoid any potential injuries from flying metal chips or sharp edges. Secondly, ensure that the material being cut is securely clamped onto the frame before making any cuts to prevent slipping or misalignment.

The thickness and hardness of the material also play a role in determining the effectiveness of using a guillotine for cutting aluminium products.

It's worth noting that while guillotines offer precise cutting capabilities for straight lines and angles, they may not be suitable for more complex shapes or curves. In these cases, alternative cutting methods like waterjet or laser cutting may be more appropriate.

Guillotines are a versatile and efficient tool for cutting aluminium products. Their ability to produce clean and accurate cuts at a quick pace makes them an essential addition to any workshop or manufacturing facility. However, it's crucial to follow safety protocols and consider the material's thickness before using this machine for optimal results.

Plasma Cutting

Plasma cutting is a versatile and efficient method for cutting aluminium products. It utilizes an electrically conductive gas, such as compressed air, to create a high-temperature plasma arc that melts through the metal. This process allows for precise and smooth cuts with minimal distortion.

One of the main advantages of plasma cutting is its speed. Compared to traditional methods like hacksaws or shears, plasma cutting can complete a cut in a fraction of the time. This makes it an ideal choice for large-scale industrial projects where time is of the essence.

Furthermore, plasma cutting provides exceptional precision and accuracy. The heat from the plasma arc is concentrated on a small area, resulting in clean edges and minimal material loss. This makes it perfect for intricate designs and shapes that require precise measurements.

Another benefit of using plasma cutting for aluminium products is its ability to cut through thick materials. While other methods may struggle with thicker sheets of metal, plasma cutting can easily handle them without compromising on quality or speed.

Additionally, one significant advantage of using plasma cutting for aluminium products is its versatility. It can be used on various types of aluminium alloys, including those with higher melting points or harder surfaces. This flexibility makes it suitable for a wide range of applications in industries such as construction, automotive manufacturing, and aerospace.

One common misconception about plasma cutting is that it produces excessive heat which can cause warping or distortion in the metal being cut. However, modern advancements have allowed for greater control over the intensity and direction of the heat generated by the plasma cutter. As a result, this method produces minimal thermal effects on the surrounding material while maintaining high-quality cuts.

When it comes to safety considerations, proper training and protective gear are essential when operating a plasma cutter due to its use of high voltage electricity and intense heat. Operators must wear appropriate eye protection as well as gloves and aprons made from non-flammable materials.

If you are looking to cut aluminium products with speed, precision, and versatility, plasma cutting is an excellent choice. Its ability to handle thicker materials and produce clean edges make it a popular method in various industries. However, proper training and safety measures must be taken when using this method for cutting aluminium or any other metals.

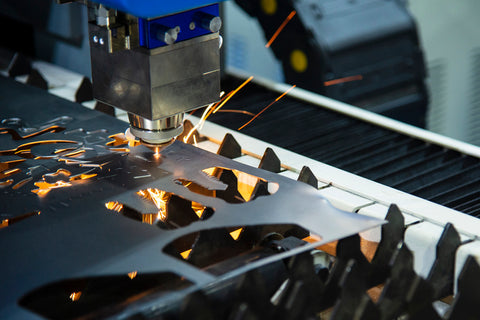

Laser Cutting

Laser cutting is a popular and effective method for cutting aluminium products due to its precision, speed, and versatility. This process uses a high-powered laser beam to melt or vaporize the material, creating an accurate and clean cut.

One of the main advantages of laser cutting is its ability to produce intricate designs with minimal distortion. This makes it ideal for cutting complex shapes and patterns in aluminium sheets and other products. It also has a high level of accuracy, with some machines able to cut within 0.025 mm, ensuring precise cuts every time.

In addition, laser cutting is known for its speed and efficiency. The process can be completed quickly, making it suitable for large production runs. It also eliminates the need for secondary finishing processes as the edges are smooth and burr-free.

There are two types of lasers commonly used in aluminium cutting - CO2 lasers and fibre lasers. CO2 lasers use a gas mixture to create the laser beam while fibre lasers use solid-state technology making them more energy-efficient and cost-effective.

When using laser cutting on aluminium products, there are certain factors that need to be considered to ensure optimal results. Firstly, the thickness of the material should not exceed 25mm as this can cause warping or distortion during the cutting process. Additionally, it is important to choose the right type of gas mixture or assist gas (such as nitrogen) depending on the thickness of the aluminium being cut.

Another consideration is choosing between continuous wave (CW) or pulsed laser beams. CW produces a steady stream of energy which is better suited for thicker materials while pulsed beams provide bursts of energy that are more suitable for thinner materials.

It is important to note that safety precautions must be taken when operating a laser cutter as it involves working with high temperatures and potentially hazardous fumes from melting metal. Protective gear such as goggles must be always worn when operating these machines.

Laser cutting offers numerous advantages for cutting aluminium products and is a popular choice due to its precision, speed, and versatility. However, it is important to understand the various factors involved in the process to ensure optimal results and safety. With the proper knowledge and precautions, laser cutting can be an efficient and effective method for producing high-quality aluminium products.

Waterjet Cutting

Water jet cutting is a modern technology that utilises a high-pressure stream of water to cut through various materials, including metals. This technique is often referred to as “water jet machining” or “hydro-jet cutting.”

The principle behind water jet cutting is simple yet effective. A pump pressurizes the water, creating a powerful stream that can reach pressures up to 60,000-90,000 pounds per square inch (psi). The pressurized water then passes through a small nozzle which focuses the stream into a fine jet with incredible cutting power.

But how does this work for metal cutting? Well, the answer lies in the addition of abrasive particles to the water stream. These tiny particles, usually made of garnet or aluminium oxide, are mixed with the pressurized water and act as “cutting tools.” As the abrasive-laden water hits the metal surface, it erodes away material at an extremely fast rate.

One significant advantage of using this method for metal cutting is its ability to create precise cuts without heat distortion or mechanical stress on the material. Traditional methods such as sawing or drilling generate excessive heat which can alter the properties of metals and compromise their structural integrity. With water jet cutting, there is no heat produced during the process, making it ideal for materials that are sensitive to temperature changes like aluminium.

Moreover, since there is no physical contact between the machine and metal piece during cutting, there is minimal risk of damage or warping. This makes it an excellent option for intricate designs and delicate materials that require precision cuts.

Another benefit of using water jets for metal cutting is its versatility. It can easily cut through various thicknesses and types of metals such as aluminium alloys, stainless steel, copper alloys, titanium alloys and more. This flexibility allows businesses from different industries – from automotive to aerospace –to use this technology for their metal cutting needs.

Furthermore, water jet cutting is environmentally friendly. The process does not generate any hazardous fumes or waste, making it a sustainable option for companies looking to reduce their carbon footprint.

Safety Precautions for Cutting Aluminium

Cutting aluminium can be a daunting task, as the metal is known for its sharp edges and tendency to cause injuries if proper safety precautions are not taken. Therefore, it is crucial to follow certain safety measures when cutting aluminium products to ensure the well-being of yourself and those around you.

- Wear Protective Gear:

The first and most important precaution before any cutting operation is to wear protective gear. When working with aluminium, it is essential to wear gloves, eye protection, and a dust mask to prevent any cuts or exposure to fine particles that may cause harm.

- Choose the Right Cutting Tool:

When selecting a cutting tool for aluminium, it is crucial to choose one with appropriate blade strength and suitable speed settings. Hacksaws or circular saws with carbide-tipped blades are recommended for manual cutting of thinner sheets or profiles. For thicker pieces or precision cuttings, waterjet cutting machines are an ideal choice.

- Keep the Work Area Clean:

Before beginning the cutting process, make sure your work area is clean from any debris or clutter that can cause accidents or damage to your tools. A tidy workspace also allows for better manoeuvring of the material during cutting operations.

- Securely Clamp the Material:

Aluminium tends to move around during cutting due to its smooth surface texture; therefore, it is essential to clamp down on the material securely before starting any cuts. This will hold the piece in place and prevent unwanted movements that may result in injuries.

- Follow Proper Technique:

Using improper techniques while cutting aluminium can lead to serious accidents such as kickbacks or blade breakage. It is crucial always to keep both hands on the tool while applying consistent pressure throughout the cut instead of pushing too hard at once.

- Watch Out for Burrs and Sharp Edges:

After completing a cut on aluminium material, there may be sharp edges or burrs left behind that can cause cuts if touched without caution. Use sandpaper or a deburring tool to smoothen the edges and prevent any potential injuries.

Aluminium scraps, shavings, and dust can be hazardous if not disposed of properly. Make sure to store them in designated containers and dispose of them according to local regulations. Never leave them lying around the work area as they can cause slips, trips, or falls.

By following these safety precautions when cutting aluminium products, you can ensure both your own safety and the quality of your final product. Remember always to take your time and prioritise safety over speed while working with this versatile yet potentially dangerous metal.

At the Aluminium Warehouse, we offer free cut to size on all our products.

Browse our full range of Aluminium products or take a look at our Aluminium Sheet and Aluminium Plate cut to size.