At The Aluminium Warehouse, we are dedicated to meeting all your Stainless Steel needs. Our wide range of products includes box section, angles, bars, tubes, sheets and splashbacks. Whether you are a business or an individual, we offer bulk supplies or smaller quantities for DIY projects. As your go-to supplier for high-quality stainless steel products at competitive prices, we have over 50 years of experience and a knowledgeable team ready to provide advice and guidance. Additionally, make use of our complimentary precision cutting services on all our products.

Stainless Steel

What is Stainless Steel?

Stainless Steel is a versatile and durable metal alloy made from a combination of iron, chromium, and other elements. It is highly resistant to corrosion, making it perfect for use in a variety of industries such as construction, manufacturing, and food processing. Its strength and aesthetic appeal also make it a popular choice for DIY projects and home improvement. With its ability to withstand high temperatures and harsh environments, Stainless Steel is the go-to material for businesses and individuals seeking reliability and longevity in their products and projects. Read our full article on this topic here - what is stainless steel?.

What is Stainless Steel used for?

Stainless Steel is a versatile and durable material that is commonly used in various industries, including construction, manufacturing, and transportation. Due to its corrosion-resistant properties, it is often used in outdoor structures such as bridges and vehicles like airplanes and trains. It is also commonly used in household appliances and kitchenware due to its hygienic qualities. In the DIY world, stainless steel can be found in tools, hardware, and even as a decorative element for home projects. With its strength and resistance to wear and tear, Stainless Steel is a reliable choice for any project or product that requires long-lasting durability.

What are the most popular Stainlees Steel products?

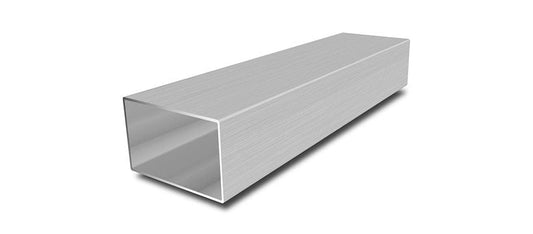

As a leading supplier of stainless steel products, we understand that the needs and preferences of our customers can vary. However, based on our extensive research and experience, we have found that the most popular stainless steel products are box sections, angles, flat bars/strips, and sheets. These versatile and durable products are essential for various industries such as construction, manufacturing, and DIY projects. We take great pride in providing high-quality stainless steel products to cater to the diverse needs of our customers. Read our in-depth guides on stainless steel box section and stainless steel grades for more details.

Order your Stainless Steel today from aluminiumwarehouse.

Free delivery on orders over £75 to UK Mainland. Collect reward points with every order.

Please call us for free on 0800 520 0729 should you need any advice on our brass products.